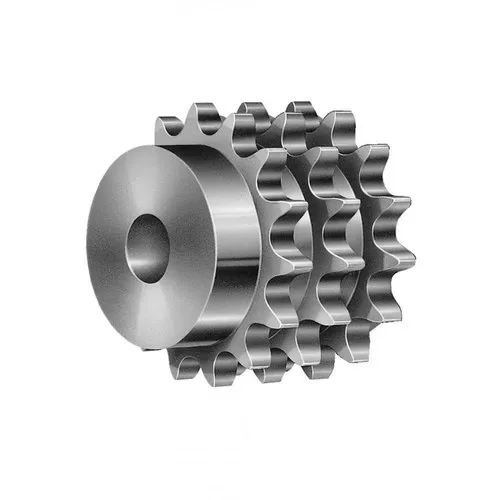

Sprocket

Triplex Sprocket

| Material | Carbon Steel |

| Usage/Application | Industrial Machinery |

| Hardness | 60 HRC |

| Surface Finishing | Polished |

| Diameter | 76 mm |

| Country of Origin | Made in India |

Description of Triplex Sprocket

A triplex sprocket is a specialized type of sprocket used in various machinery and equipment to transmit rotary motion and power from one component to another. It is called "triplex" because it has three sets of teeth or chain grooves around its circumference, allowing it to engage with a corresponding triple-strand roller chain. These sprockets are a key component in chain-driven systems and are known for their durability and efficiency in power transmission.

Key Features and Components

- Sprocket Teeth : The primary function of a triplex sprocket is to engage with and drive a roller chain. Each set of teeth on the sprocket corresponds to one strand of the chain, allowing for simultaneous engagement with three strands. The shape and size of the teeth are designed to match the pitch of the chain, ensuring a secure connection.

- Hub : The hub of the triplex sprocket is the central part where it mounts onto a shaft. It typically has a hole in the center that allows for secure attachment to the shaft through various methods, such as set screws, keyways, or bushings.

- Bolt Holes : Triplex sprockets may also have bolt holes around the perimeter of the hub. These holes enable the sprocket to be bolted onto a hub or other mounting surface, enhancing stability and preventing slippage.

Function and Applications

- Industrial Machinery : Triplex sprockets are often found in manufacturing machinery, conveyor systems, and material handling equipment to transmit power and control the movement of components.

- Agricultural Machinery : Farm equipment, such as tractors and combines, frequently utilizes triplex sprockets to drive various components like belts, pulleys, and augers.

- Mining Equipment : In mining and quarrying operations, triplex sprockets are used to drive conveyor belts, crushers, and other heavy machinery.

- Construction Machinery : Earthmoving and construction equipment rely on triplex sprockets to control the movement of tracks, chains, and other components.

Triplex sprockets play a vital role in power transmission systems that use roller chains. They are commonly used in a variety of applications, including:

Advantages

- High Load Capacity : Triplex sprockets can handle heavy loads and transmit substantial amounts of power due to their triple-strand design.

- Increased Chain Life : The use of multiple strands reduces wear and distributes the load evenly across the chain, extending its service life.

- Precision Power Transmission : Triplex sprockets provide accurate and synchronized power transmission, ensuring efficient and reliable operation of machinery.

- Customization : They are available in various sizes, tooth configurations, and materials to suit specific applications.

Conclusion

Triplex sprockets are essential components in chain and sprocket drive systems, offering robust and efficient power transmission capabilities. Their versatility and reliability make them suitable for a wide range of industrial and mechanical applications where precise and synchronized motion is required.